Nippon Paint Marine Coatings supplies customers around the world with high-quality products, technical services and know-how by making use of Nippon Paint Group’s global bases in manufacturing, sales, service and logistics networks.

OPERATIONAL EFFICIENCY AND ASSET PROTECTION

Reducing operating cost, increasing uptime, and ensuring long-term investment protection are the key objectives which make Nippon Paint innovative

Best in class fuel-saving antifouling paint and long-lasting corrosion protection systems are the tools brand provides allowing shipowners to stay ahead

140

years of innovations

For more than 140 years, Nippon Paint Marine has been at the forefront of the world's most challenging environment for coatings; marine

Fuel saving antifouling

Anticorrosive coatings

Non-slip coatings

Heat resistance coatings

Solar reflecting

Сoating system

Heavy duty coatings

Cosmetic finish coatings

OUR PRODUCTS BY

APPLICATIONS

Newbuilding

Seastock

At new construction, choosing the right system is critical for the vessel build process.

Seastock paints keep your asset in tip-top condition and reduce long-term maintenance.

more ⟶

more ⟶

SOLUTIONS BY

VESSEL AREA

NANO-Technology

Self Polishing & Self Smoothing Anti-Fouling Paint with NANO-Technology. Combining both hydrophilic & hydrophobic in nano-structure.

•

Maintaining precise, stable and sustainable antifouling performance

•

Improved operational efficiency

•

Environmental protection

Focus on the surficial film of coating

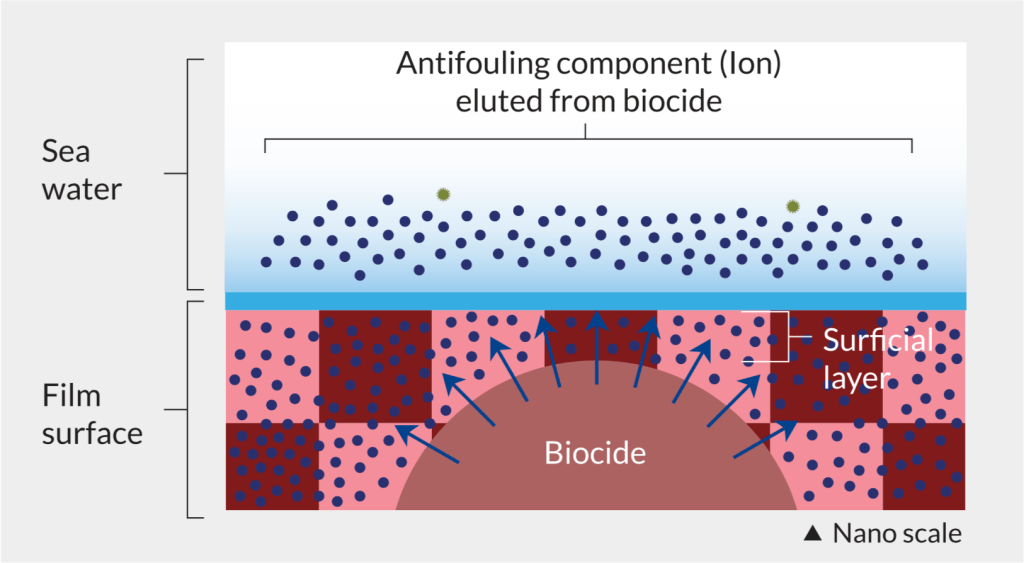

To develop a new antifouling paint, Nippon Paint Marine adopted a method of modifying the surficial film of coating rather than selecting an biocides. Aiming for “higher antifouling performance”, our unique nanodomain technology is applied on the surficial film of the coating.

Control of elution of antifouling components

To develop the antifouling function, an antifouling component emitted from the biocides is required. The widespread and stable elution of antifouling components was made possible by the hydrophilic & hydrophobic nanodomain structure. That is, the antifouling component is diffused in the surficial film of the coating by the hydrophilic domain and retained by the hydrophobic domain, and is stably eluted over a wide range.

High Solid Content

Benefit

•

Reduction of air pollution

•

Improved coating efficiency

Same day delivery

Best quality available

Most products in stock

24/7 customer service

Worldwide distribution